The Top Benefits of Metal Plate Laser Cutting Services

Discover why manufacturers are turning to lasers for metal shaping that’s a cut above the rest.

Manufacturing has been known as an industry that can solve the world’s toughest problems and has always been on the forefront of innovation.

As new and combination materials emerge and the need for speed and precision seems to grow faster by the day, manufacturers are trying new techniques for metal laser shaping and cutting.

They’re choosing metal plate laser cutting services because they combine precision, speed, flexibility, and cost efficiency in ways that are hard to match with traditional cutting methods, like plasma, waterjet, or mechanical cutting.

Here are some of the biggest benefits of using metal plate laser cutting for some of your most complex projects.

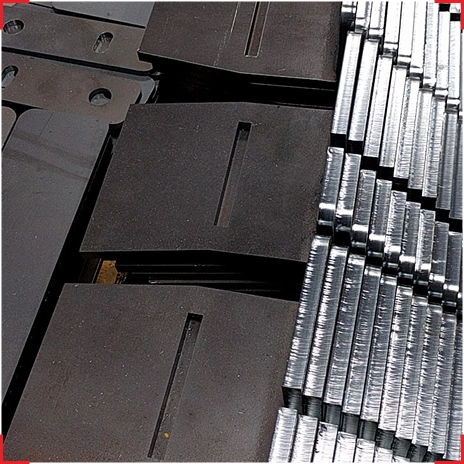

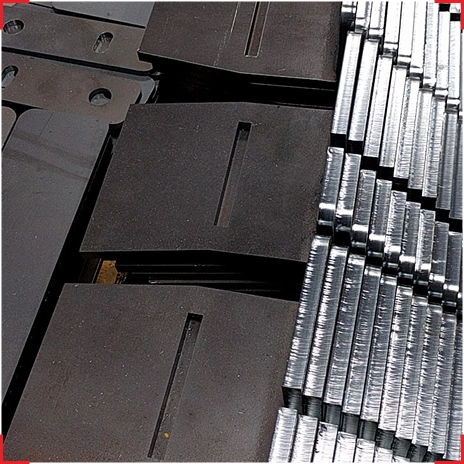

01. High Precision and Tight Tolerances

Laser cutting delivers extremely accurate cuts, often within ±0.005–0.010 inches, which is critical for:

Parts that must fit together without secondary machining

Parts that must fit together without secondary machining

Complex geometries, slots, and fine features

Complex geometries, slots, and fine features

Consistent repeatability across production runs

Consistent repeatability across production runs

Big takeaway: This level of precision reduces scrap, rework, and downstream assembly issues.

02. Fast Turnaround and Production Speed

Laser cutting is a non-contact process, which means your equipment and metals experience positive advantages such as:

- No tool wear or frequent tool changes

- High cutting speeds, especially on thin to mid-thickness plate

- Rapid setup when switching between part designs

Big takeaway: Laser cutting services help meet short lead times and can prototype quickly before scaling production.

03. Design Flexibility and Complexity

Lasers excel at cutting:

- Intricate shapes

- Small holes

- Tight internal corners

- Text, serial numbers, and part markings

Big takeaway: You get freedom in design and production when you use laser cutting, especially for sheet metal and plate-based components.

04. Reduced Secondary Operations

Big takeaway: Parts often require less deburring, grinding, or finishing, lowering labor costs and speeding up delivery.

Laser cutting often minimizes the secondary operations needed in the metal shaping process because it produces:

- Clean edges

- Minimal burrs

- Narrow heat-affected zones (HAZ)

05. Cost Efficiency for Low-to-Medium Volumes

For many manufacturers, outsourcing metal laser cutting services can help:

Avoid capital investment in high-cost laser machines

Avoid capital investment in high-cost laser machines

Eliminate maintenance, training, and floor space requirements

Eliminate maintenance, training, and floor space requirements

Make small-batch and custom work economically viable

Make small-batch and custom work economically viable

Big takeaway: Partnering with a trusted laser cutting shop is especially valuable for job shops, OEMs, and contract manufacturers.

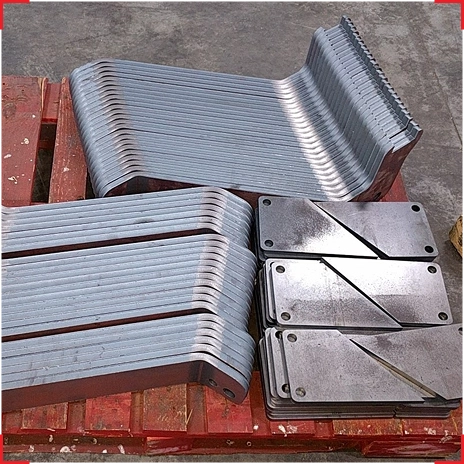

06. Material Versatility

Laser cutting services can handle a wide range of metals, including:

- Carbon steel

- Stainless steel

- Aluminum

- Brass and copper (with fiber lasers)

Big takeaway: Laser cutting is a single process that supports multiple material types and thicknesses.

07. Better Material Utilization (Lower Scrap)

Modern laser cutting uses advanced nesting software to:

- Maximize parts per sheet or plate

- Minimize drop material

- Reduce raw material costs

Big takeaway: Laser cutting services help meet short lead times and can prototype quickly before scaling production.

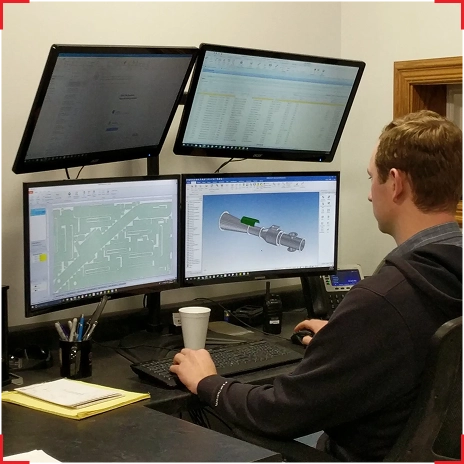

08. Easy Integration with Digital Manufacturing

We live in a digital world, and laser cutting fits naturally into modern manufacturing workflows, such as:

- CAD-to-CAM automation

- Direct use of DXF/DWG files

- Fast design revisions without tooling changes

Big takeaway: Laser cutting supports agile manufacturing, mass customization, and rapid engineering changes.

09. Scalability Without Long-Term Commitment

Manufacturers often use laser cutting services to:

- Bridge capacity gaps

- Support demand spikes

- Validate designs before investing in tooling

Big takeaway: It’s a low-risk way to scale production without locking into fixed costs.

SteinerZ Delivers Metal Plate Laser Cutting Services Quickly & Accurately

SteinerZ Fabrication offers high-precision laser cutting, forming, machining, and welding services all under one roof.

Turnarounds as fast as 2 weeks

±.005” laser tolerances

Full-service fabrication

Expedited options available

Customer-focused service

ISO 9001:2015 certified

Ask us your metal laser cutting questions!

Not sure if laser cutting services are right for you? Our experts will walk you through it and answer all your questions.