What You Need to Know Before Getting Started with Industrial Laser Cutting

Wondering if industrial laser cutting is right for your parts? Here are the basics you need to know.

Industrial laser cutting seems pretty straightforward. It’s a laser cutting technique that produces industrial parts, right?

At a very basic level, yes. But if you have metal parts that will be performing some heavy-duty industrial work, you’ll want to understand a few core concepts before you partner with a laser cutting specialist.

Here’s a practical overview of everything you need to know about industrial laser cutting.

01. Laser Cutting Basics (What’s Actually Happening)

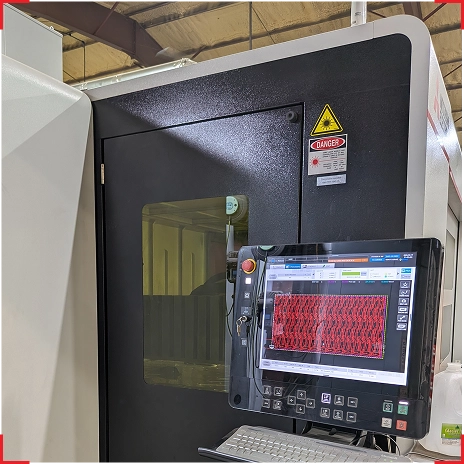

Industrial laser cutting uses a high-energy focused beam to melt, burn, or vaporize material along a programmed path.

Here are the key components that make this possible:

- CAD-to-CAM automation

- Direct use of DXF/DWG files

- Fast design revisions without tooling changes

- CNC motion system

The laser heats the material and the assist gas blows molten material out of the kerf to create a clean cut.

02. Fiber vs. CO₂ Lasers

Most modern shops use fiber lasers, but there are still quite a few that use CO₂ lasers, so it’s worth knowing the difference.

- Fiber Lasers

- Best for steel, stainless, aluminum, copper, brass

- Faster cutting speeds

- Lower maintenance

- More energy efficient

- Fiber Lasers

- Best for steel, stainless, aluminum, copper, brass

- Faster cutting speeds

- Lower maintenance

- More energy efficient

- CO₂ Lasers

- Historically good for thicker, mild steel

- Better edge quality on some non-metals

- Higher maintenance (mirrors, gas)

- CO₂ Lasers

- Historically good for thicker, mild steel

- Better edge quality on some non-metals

- Higher maintenance (mirrors, gas)

03. Material Matters A Lot

Different materials behave very differently under a laser, so if you’re looking for a laser cutting partner, you’ll want to make sure they understand the type of metal you’re using and ask about their experience cutting various types of metals.

Reflectivity

(aluminum, copper, brass can reflect energy back into the head)

Thickness

(thicker = slower, more power, more gas)

Alloy consistency

(cheap steel cuts worse than clean steel)

Surface condition

(rust, oil, mill scale affect cut quality)

04. Assist Gas Is Not Optional

Most people don’t think about gas when they hear “laser cutting,” but the assist gas is just as important as the laser itself. Oxygen, Nitrogen, and compressed air are all used, and they each have their pros and cons.

- Oxygen

- Used for mild steel

- Faster cutting

- Leaves an oxidized edge

- Oxygen

- Used for mild steel

- Faster cutting

- Leaves an oxidized edge

- Nitrogen

- Used for stainless & aluminum

- Clean, shiny edges

- Higher gas cost

- Nitrogen

- Used for stainless & aluminum

- Clean, shiny edges

- Higher gas cost

- Compressed Air

- Lower cost option

- More dross, less edge quality

- Compressed Air

- Lower cost option

- More dross, less edge quality

The bottom line is that it’s very important to consider which assist gas is right for your chosen metal and desired product because the wrong gas leads to a bad cut, even with perfect power settings.

05. Better Material Utilization (Lower Scrap)

In some ways, laser cutting is a more streamlined, simpler version of more traditional metal shaping techniques, but there are still things to consider for a good laser cut that go beyond the laser. Cut quality comes from the balance of:

- Laser power

- Cutting speed

- Focus position

- Gas pressure

Too fast

incomplete cut

Too slow

wide kerf, heavy dross

Wrong focus

rough edges or taper

04. Safety Is Essential

All of manufacturing is made of rigorous safety measures because we’re working with big, powerful machines and metal parts. Laser cutting is no different, and industrial lasers are Class 4 systems, which means that serious hazards exist.

Key safety points:

- Never defeat interlocks

- Watch for reflections on shiny metals

- Fire risk with thin material and oxygen

- Fumes require proper extraction

Important thing to note: Laser cutting fires happen more often than people expect, so you’ll want to ask about fire safety and compliance measures if you’re vetting a laser cutting partner.

07. Maintenance Affects Quality

Cut problems are often caused by basic maintenance issues, which can cause even bigger quality problems if left unchecked. Small things can have a big impact on quality control, including elements such as:

Dirty protective window

Dirty protective window

Damaged nozzle

Damaged nozzle

Incorrect nozzle centering

Incorrect nozzle centering

Worn lenses

Worn lenses

Daily checks save hours of troubleshooting, so you’ll want to incorporate frequent and regular checks into your maintenance and quality process, or if you’re relying on a partner, ask them about their quality systems.

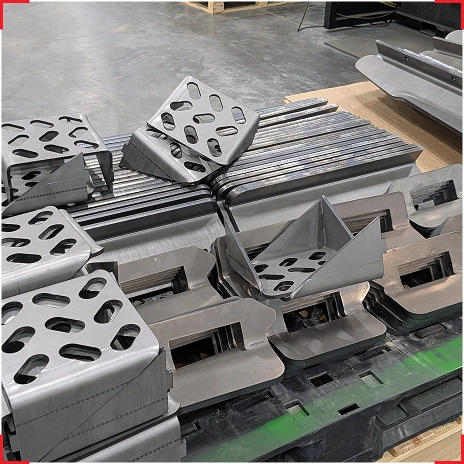

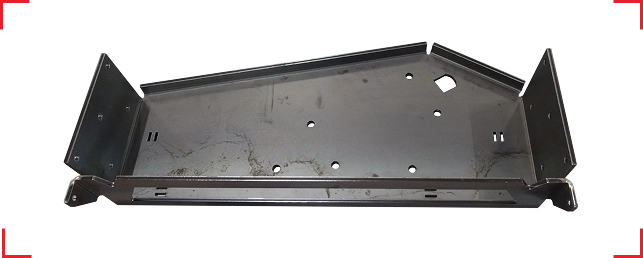

SteinerZ is a Trusted Industrial Laser Cutting Partner

SteinerZ Fabrication offers high-precision laser cutting, forming, machining, and welding services all under one roof.

Turnarounds as fast as 2 weeks

±.005” laser tolerances

Full-service fabrication

Expedited options available

Customer-focused service

ISO 9001:2015 certified

Ask us your industrial laser cutting questions!

Not sure if laser cutting services are right for you? Our experts will walk you through it and answer all your questions.