How Precision Laser Cutting Will Get Even Better in 2026

Explore the ways precision laser cutting will help manufacturers produce more precise, unique metal parts.

First thing first: Why do manufacturers like precision laser cutting?

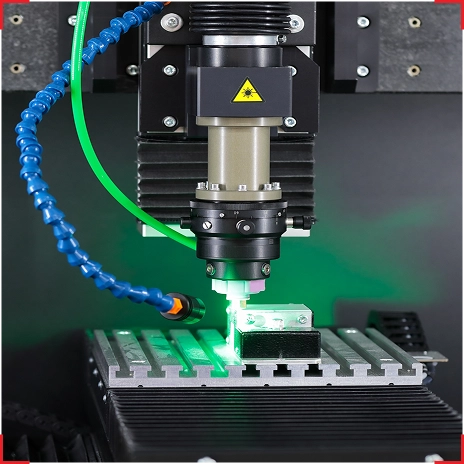

Precision laser cutting uses a highly focused laser beam to vaporize, melt, or blow away material along a defined path.

This technique gives manufacturers extremely accurate and repeatable cuts with minimal burrs and narrow kerfs. It’s widely used in some of our most in-demand, important industries including industrial fabrication, electronics, automotive, aerospace, and medical.

The Top 5 New Advances Coming to Precision Laser Cutting

01. Advanced Laser Sources

The heartbeat of a shop is its equipment. Instead of open-ended questions like, “What does your equipment do?” try and get specific. Ask questions related to these technical aspects:

Fiber Lasers

Dominant in precision cutting thanks to high beam quality, energy efficiency, and faster cutting speeds

Ultrafast (Femtosecond) Lasers

Ultra-short pulses minimize heat-affected zones and allow precision on heat-sensitive or micro-scale features

Green Lasers

Better at cutting reflective materials like copper, brass, gold, which is important for electronics & jewelry

Together, these sources enable higher accuracy, reduced thermal distortion, and broader material support.

02. AI, Machine Vision, & Smart Controls

In 2026, precision laser cutting systems will use more:

AI/ML algorithms for real-time optimization of beam paths and cutting parameters

AI/ML algorithms for real-time optimization of beam paths and cutting parameters

Predictive maintenance & analytics via sensors/IoT to reduce downtime

Predictive maintenance & analytics via sensors/IoT to reduce downtime

Edge computing and material recognition to auto-adjust power/speed based on material type

Edge computing and material recognition to auto-adjust power/speed based on material type

These technologies will be key in boosting throughput, reducing scrap, and improving consistency.

03. Automation & Industry 4.0

Related to the point above, precision laser systems will start becoming a part of broader smart factories with:

- Automated material loading/unloading

- Centralized production scheduling and monitoring

- Integration with MES/ERP systems

This trend is vital for scalability and high-volume precision applications.

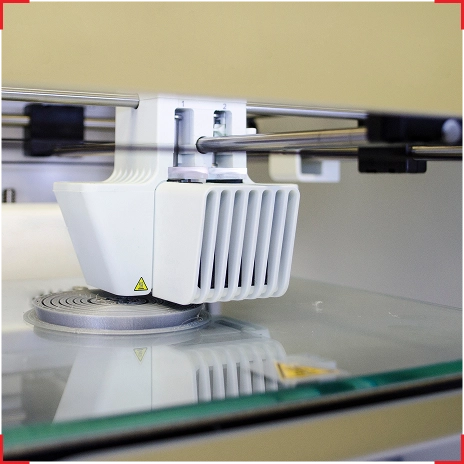

04. Hybrid Manufacturing

We’re seeing a trend of manufacturers turning to hybrid systems that combine laser cutting with other processes (e.g., additive manufacturing, milling) on a single platform.

This will allow shops to produce complex parts with fewer setups.

05. Sustainability & Efficiency

Modern precision laser cutting machines will continue to help make our world a more sustainable, greener place to live by focusing on:

- Lower power consumption

- Reduced waste and cleaner cutting processes

- More efficient lasers than older CO₂ systems

Summary: What Matters for Precision Laser Cutting in 2026

To succeed with precision laser cutting today and tomorrow, manufacturers who choose to use precision laser cutting should spend time:

Choosing the right laser source for your material and tolerance needs.

Choosing the right laser source for your material and tolerance needs.

Leveraging AI and automation to maximize throughput and quality.

Leveraging AI and automation to maximize throughput and quality.

Planning for skills and safety in operation and maintenance.

Planning for skills and safety in operation and maintenance.

Aligning investments with your production goals — balancing cost with precision and speed.

Aligning investments with your production goals — balancing cost with precision and speed.

SteinerZ is a Trusted Precision Laser Cutting Partner

SteinerZ Fabrication offers high-precision laser cutting, forming, machining, and welding services all under one roof.

Turnarounds as fast as 2 weeks

±.005” laser tolerances

Full-service fabrication

Expedited options available

Customer-focused service

ISO 9001:2015 certified

Ask us your precision laser cutting questions!

Not sure if laser cutting services are right for you? Our experts will walk you through it and answer all your questions.